By taking advantage of Viessmann weather compensation technology, you can save an amazing 15% extra on your fuel bills.

Not only could you be saving money, but carbon emissions too. Which need to be net-zero by 2050, accordingly to the latest government guidelines, so a step in the right direction.

New conventional boilers offer a saving of 35%, with an opportunity to save an additional 15% if you invest in Viessmann’s weather compensating technology with very clever controls.

Technical Information:

So how does it work? In short the weather compensation controls ensure the boiler burns exactly the amount of fuel required to match the heat loss from the building.

A small temperature sensor is located on the outside of the building. This is wired into the internal controls of the boiler and information about the outside temperature is sent to the boiler controller constantly.

When the temperature changes outside the boiler responds and starts to increase or decrease the radiator temperature to compensate. This pro-active mechanism means that people inside the building won’t even notice that the temperature has changed.

So weather compensation controls enable the boiler to respond to outside temperature changes and adjust the radiator output, to maintain a constant temperature indoors.

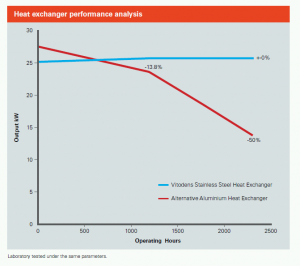

The diagrams below shows the comparison of a heating system without weather compensation.

This also means the boiler isn’t working to hard, which in turn adds to its life span.

Condensing Effect:

Viessmann weather compensation technology enables the condensing boiler, which already has dramatically increased efficiency, by recovering latent heat in the flue. But also by enabling the boiler to operate at lower temperatures meaning it can condense for longer.

Controls:

The Viessmann Vitodens 200-W weather compensating controls are very sophisticated. Giving a heat curve that can be adjusted to finely tune the household and the type of building construction. These controls also gives you the added benefit of:

- Night set-back option.

- Built-in 7 day programmer.

- Built-in pump logic for optimised pump over-run to reduce power consumption.

- Morning booster function, it lifts the flow temperature by 20% first thing in the morning to heat the house faster.