Stainless steel is the key and here is why. . .

Heating technology should work together to ensure the smooth operation of the entire system – from boiler via burner, control unit and heat exchanger, to deliver the highest possible operational reliability. Today, domestic and commercial boiler technology demands the most reliable, energy efficient components. Contact us for a quotation

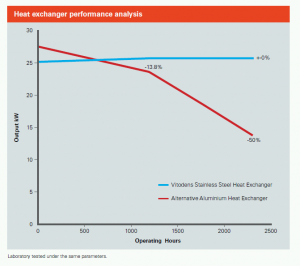

A key component in choosing the right system, is the heat exchanger within the boiler, as maintenance costs, durability and product lifetime should all be considered when buying a boiler. As the two most common types of heat exchanger in the UK condensing boiler market, we have examined the differences between stainless steel and aluminium to offer a comparison of quality and longevity.

Stainless Steel Heat Exchangers:

Used by Viessmann throughout its entire condensing boiler range, stainless steel heat exchangers provide a high resistance to corrosion in a wide variety of pH levels, therefore increasing the useful life of your boiler. This provides long term value for money and requires less system downtime due to maintenance.

Important points to consider:

- Increases useful life of your boiler.

- Less downtime due to maintenance.

- Does not require use of system inhibitors.

- Recommended for filling with potable water (drinking water) no inhibitors required.

- Self-cleaning.

- Higher grade corrosion resistant material.

Aluminium Heat Exchangers:

A lightweight and alternative option, Aluminium heat exchangers also provide high heat transfer but require special inhibitors when maintaining the system, which if not used can result in a high risk of damage to the boiler. Annual maintenance is also vital to remove aluminium oxides, which can build up and clog the condensate line.

Important points to consider:

- pH treatment critical to longevity of the heat exchanger.

- Artificially softened water not permitted.

- Aluminium material corrodes through aluminium oxide build up and erodes further at high flow rates.

- Reduced lifetime of the heat exchanger.

- Cheaper to manufacture than stainless steel.

All Viessmann gas condensing boilers are equipped with stainless steel Inox-Radial heat exchangers. This technology brings with it an extremely high efficiency rate of 98 percent and exceptionally reliable and efficient operation during its long service life.

Viessmann guarantees the Inox-Radial heat exchanger for ten years against leaks resulting from corrosion.